What Is Celadon?

Celadon can be defined as a type of glaze used in East Asian pottery. But the term has come to represent many types of glazes. The exact definition will differ, depending on the region and time it came from. In Korea, “celadon” references a variety of glazes in a pale green color. To modern potters, “celadon” can be any translucent glaze, regardless of the color.

For ceramic artist Xu De Jia, “celadon” is his signature. The Taiwanese artist has perfected a bluish-green glaze with a satiny texture. After many years of studying historical styles, this has become his specialty. His goal is to replicate the famed celadon glazes of the Imperial Ru Kiln. This short lived kiln rose to legendary status after the fall of the Northern Song Dynasty.

The Ru Kiln, one of the Five Great Kilns of the Song Dynasty, operated for a short period of only about 20 years. When the kiln was functioning, it produced acclaimed pottery for the imperial family. After the kiln's abandonment, the celadon wares made there only grew in reputation. But along with the kiln site, the glaze recipe was lost. Today, there are less than 100 authentic Ru Kiln pieces left intact.

How Is Celadon Made?

All ceramic glazes are a mixture of minerals, which act as colorants. These are added to a base of silica that will melt and turn to glass when heated in a kiln. First, Xu De Jia’s ceramic pieces are wheel thrown or molded by hand. Then, they go through a low temperature firing to prepare them for the glazing process.

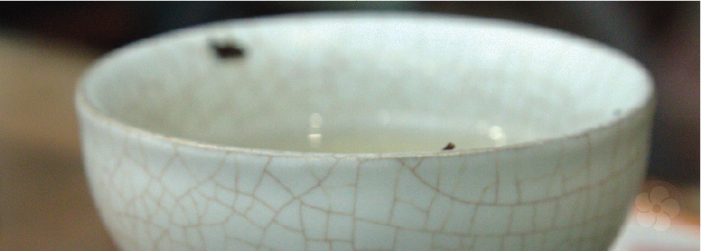

The formed pieces are then dipped into the liquid glaze before going back in the kiln. This time, the high heat vitrifies both the clay and the glaze. Here’s where things get tricky. In a gas kiln, Xu De Jia brings the temperature to over 2300°F. The silica begins to flux, and the minerals in the glaze melt. To achieve the satiny texture of his signature glaze, he must not let the temperature rise too high. This is called “under-firing” the glaze. As the pieces cool, the clay and the glaze contract and shrink. Sometimes, the two components shrink at different rates. This creates a web of small, imperceptible cracks in the surface of the glaze. Over time, these cracks will stain with tea, becoming more visible as the patina deepens.

Most of his work is in the classic robin’s egg tone of the Ru Kiln. But Xu De Jia does produce celadon glazes in other colors, and even in other historical styles like hare’s fur. His small scale production in his home’s basement studio keeps his work authentic. Each piece is formed, trimmed, and glazed by hand. No two pieces are exactly the same, and forms are rarely repeated from year to year. His work is popular for its artistic value, but each piece is also functional at the tea table.

Signs Of Quality

Xu De Jia has become well known as the best producer of Ru style glazes. At the National Palace Museum in Taipei, his work is sold in homage to their collection of Ru Kiln wares. The opaque tone and soft texture of his celadon glazes are key characteristics. They set his work apart in a world awash with modern translucent celadon.

But it is the handmade authenticity of each unique piece that makes his work fun to use. The precise details and hand carved signature are evidence that each piece is made with care. As the glaze crackles with use, the teaware seems to take on a life of it’s own. Over time, the piece develops a personality along with the patina.